Do you need effective construction solutions?

We're here to help!

Our team has years of experience and numerous successful projects in the industrial sector, from planning to execution.

Commitment to quality

At Flerimg S.R.L., we are committed to providing construction services that meet the highest quality standards. Every project is an opportunity to demonstrate our dedication and professionalism.

Infrastructure experts

Our experience in industrial buildings and civil works positions us as leaders in the sector. We have a specialized team that guarantees exceptional results on every project.

Custom projects

We offer customized solutions tailored to the specific needs of our clients. With Flerimg S.R.L., every project is unique and executed with precision.

Servicios de Construcción

Construimos el futuro, hoy.

Construction Services

We develop industrial buildings that meet the most demanding standards. Our experience ranges from industrial warehouses to electrical substations, always guaranteeing quality and safety.

Civil Works

We carry out civil works for hydrocarbon transportation systems and other vital infrastructure. Our focus on efficiency and safety allows us to successfully complete complex projects.

Project Development

We offer a comprehensive service that covers everything from planning to project execution. We ensure that we meet agreed-upon deadlines and budgets, always prioritizing customer satisfaction.

Our Projects

Quality and excellence in every work.

AllProyectos DestacadosEstudios de Caso

CIM 720 REDUCTION (REPSOL)

The company implemented the CIM 720 reduction project, which included the installation of a heater and the addition of a cover to the gas plant's operating process. These interventions optimized operating conditions, improved system efficiency, and ensured more stable and reliable operation during critical process stages.

IMPLEMENTATION OF THE THIRD UCG AT THE COLPA COMPRESSION STATION (YPFB TRANSPORTE)

The company implemented the fourth and fifth gas compression units at the Colpa Compression Station to increase operational capacity and ensure a continuous energy supply. The project included the installation of new compression equipment, a complete upgrade of the existing infrastructure, and the integration of advanced control and monitoring systems.

SAIPURÚ STATION UPGRADE (YPFB TRANSPORTE)

The company successfully completed the project to upgrade and modernize two Solar brand turbochargers, with the goal of improving the reliability, efficiency, and operational continuity of the gas compression system. The work included modernizing critical components, completely updating the control and automation systems, and optimizing thermo-mechanical performance parameters.

ASSEMBLY AND COMMISSIONING OF PALOMETA WELL X6 (SUBCONTRACTOR - END CLIENT YPFB CHACO S.A.)

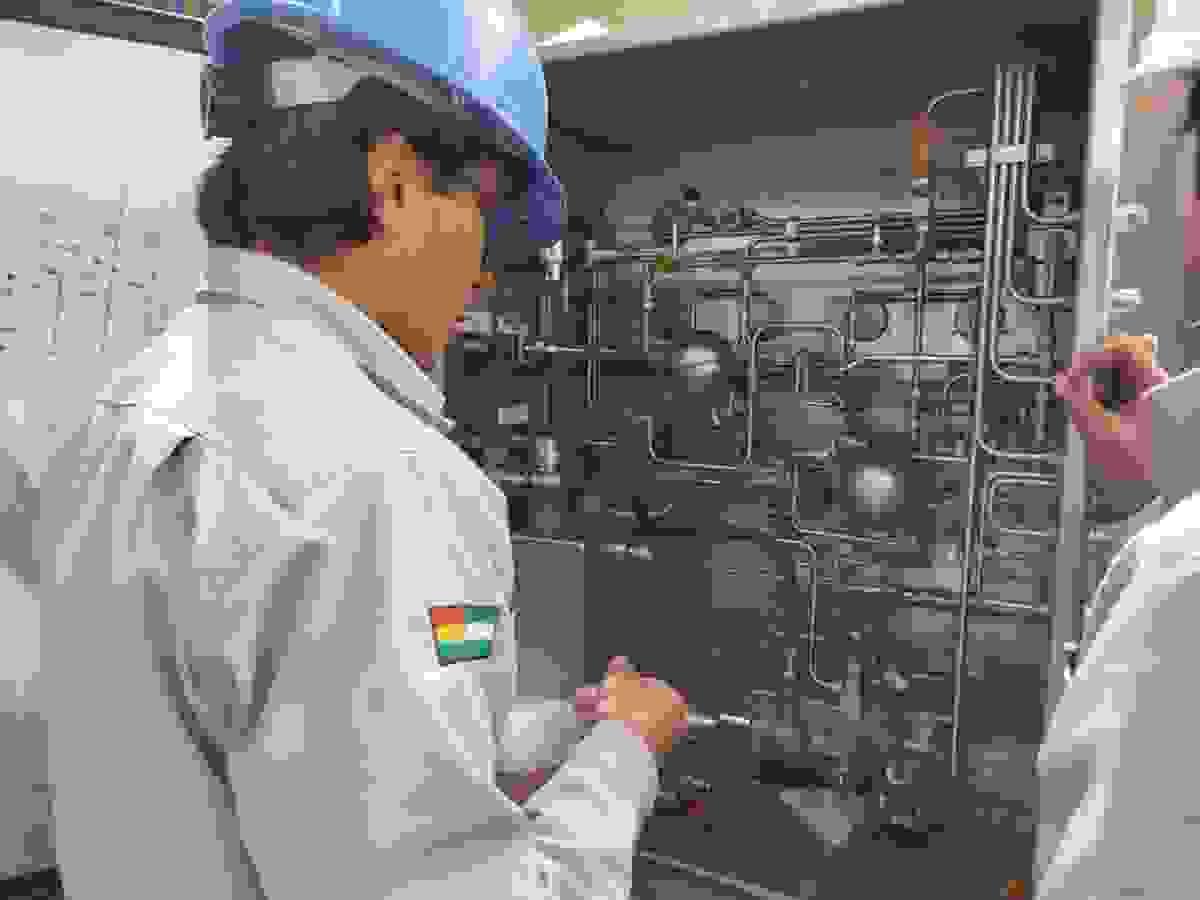

The company carried out the complete assembly of the systems associated with the Palometa X6 well, encompassing all activities related to instrumentation, equipment configuration, and functional testing. The project included the installation and calibration of measurement and control instruments, the integration of operating systems, and the commissioning process to ensure safe, efficient performance in accordance with established parameters.

INSTRUMENTATION DISASSEMBLY AND ASSEMBLY – WELL X3 CHURUMA (SUBC. / END CLIENT YPFB CHACO S.A.)

The company carried out the dismantling and subsequent reassembly of the instrumentation equipment and associated facilities at the X3 Churuma Well. The activities included the safe removal of existing devices, the installation of new measurement and control equipment, and the adaptation of the lines and auxiliary systems required for its proper operation.

UPGRADING OF VILLAMONTES POLIDUCTOS STATION (YPFB TRANSPORTE)

The project consisted of a comprehensive upgrade of the Villamontes Station, part of the multi-product pipeline system. The work included modernizing its facilities, optimizing the existing infrastructure, and implementing improvements aimed at increasing operational safety, reliability, and system efficiency.

These activities strengthened the continuity of hydrocarbon transport, ensuring compliance with technical and regulatory standards, and guaranteeing safer and more efficient operation of the station.What our customers say

Your satisfaction is our priority.

Excellent teamwork

Flerimg S.R.L. demonstrated exceptional commitment to our project. Their team was professional and met all established deadlines.

Quality and punctuality

We are very pleased with the results. The quality of the work and the punctuality of the delivery exceeded our expectations.

Custom projects

We thank Flerimg S.R.L. for tailoring every detail to our needs. Their customer service is exemplary, and the results speak for themselves.